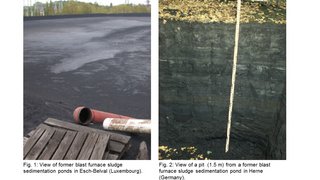

During the metallurgical process to produce pig iron in blast furnaces so called blast furnace gas is generated. Besides combustion products and solid particles of the charge material (basically Coke and Fe ores), this effluent gas contains significant amounts of low melting point elements such as zinc (Zn), lead (Pb), potassium (K), and sodium (Na) [1-3]. Dust-catchers separate off coarse particles, but the fine fraction (< 0.1 mm) is removed via wet dust separation. The generated muddy waste is referred to as blast furnace sludge (BFS) and has long been dumped to large surface landfills.

We published the first data of mercury (Hg) in BFS ranging between 0.006 and 20.8 mg kg–1 (median of 1.63 mg kg–1) in 65 samples from six former BFS sedimentation ponds and one operating BFS deposit in Europe [4]. Compared with the charge material and abundance in the Earth’s crust (0.056 mg kg–1) [5], Hg in BFS was clearly enriched in BFS with a mean enrichment factor of 50 (min.: 0.11; max.: 390). We further investigated the potential pollution status of a subset by using a sequential extraction procedure originally developed for soils and sediments [6]. Total recoveries indicated that the procedure was reliable and repeatable when adapted to this industrial waste. Mercury mainly resided in the fraction of elemental Hg (F4: 7.9 mol L–1 HNO3) rather being present as slightly soluble Hg species associated with sludge particles. Minor amounts were found as mercuric sulfide (F5: aqua regia) and Hg in crystalline metals ores and silicates (F6: residual fraction). The ecotoxically relevant fractions (F1: demineralized water; F2: 0.1 mol L–1 CH3COOH + 0.01 mol L–1 HCl) were not of significance (publication in process). It was concluded that dumped BFS has a rather low environmental risk potential regarding Hg. However, it must be considered that the analyzed BFS samples had been dumped partly for up to 80 years before sampling. Hence, Hg in mobile fractions might already have been leached out or volatilized. Therefore, we will investigate the volatilization of Hg from fresh BFS under different temperatures.

[1] Z.H. Trung, F. Kukurugya, Z. Takacova, D. Orac, M. Laubertova, A. Miskufova, T. Havlik, Acidic leaching both of zinc and iron from basic oxygen furnace sludge, J. Hazard. Mater., 192 (2011) 1100-1107.

[2] T. Mansfeldt, R. Dohrmann, Chemical and mineralogical characterization of blast-furnace sludge from an abandoned landfill, Environ. Sci. Technol., 38 (2004) 5977-5984.

[3] P. Van Herck, C. Vandecasteele, R. Swennen, R. Mortier, Zinc and lead removal from blast furnace sludge with a hydrometallurgical process, Environ. Sci. Technol., 34 (2000) 3802-3808.

[4] C. Foeldi, R. Dohrmann, T. Mansfeldt, Mercury in dumped blast furnace sludge, Chemosphere, 99 (2014) 248-253.

[5] K. Hans Wedepohl, The composition of the continental crust, Geochim. Cosmochim. Ac., 59 (1995) 1217-1232.

[6] N.S. Bloom, E. Preus, J. Katon, M. Hiltner, Selective extractions to assess the biogeochemically relevant fractionation of inorganic mercury in sediments and soils, Analytica Chimica Acta, 479 (2003) 233-248.

1. October 2014 – 31. March 2015

Corinna Földi

PhD Student

Institute of Geography

Thesis: Mercury in blast furnace sludge – Fractionation and Volatilization

Prof. Dr. Tim Mansfeldt (Soil Geography / Soil Science)

Defense: November / December 2015

Fellowship: “Antimony in roadside soils, road run-off, and affected streams” founded by the DFG (1.Juni 2015 – 31. May 2018)